荣格工业资源APP

了解工业圈,从荣格工业资源APP开始。

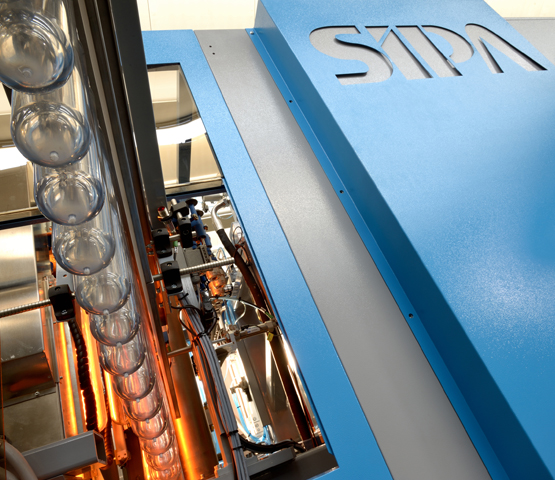

UPGRADES to SIPA’s linear blowmolding systems overcome new challenges being felt by the packaging sector. The SFL 6/8 EV now features an output of 2000 b/h/c, or 10% higher than its predecessor model, and the machine also consumes lower amounts of preform heating and bottle blowing. Another innovative feature is the new clamp opening and closing system. Directly driven by a brushless motor reducer, the clamp can adjust the width of the opening accordingly with the container to be blown in order to expand production flexibility.

The company presented the SFL 6/8 EV along with its XFORM preform injection molding units at interpack 2017. The XFORM range was extended several months ago with two smaller models when SIPA acquired Automa’s ISBM business.

The SFL 6/8 EV blow molding system enhanced for effieciecy, and more

The ECS ‘SP’ units, which were also recently upgraded, have enabled SIPA to improve its ability to provide a full service to companies producing specialty containers in all shapes and sizes, whatever the output requirement. These machines are ideal for production of containers as small as 20 mL in small to medium-sized lots, for such markets as food, detergents, pharmaceuticals, personal care, cosmetics and beauty care. They can also produce miniature drink bottles which are lightweight and break-resistant, features typically required by airlines.

These are just few of triumphs that demonstrate SIPA’s product design and expertise. Prior to interpack, Packaging R&D Director, Laurent Sigler said: “We have now notched up 30 years of packaging development expertise. In that time, we have created some 25,000 bottle designs and 30,000 preform designs, we have carried out 15,000 prototyping projects, and we have registered over 100 patents.”

The company has been providing the packaging sector with flexible bottling lines suited to match with the current trends of the beverage market, with its demands for lighter bottles, increased product differentiation, and multiple product formats, including large sizes containers. SIPA bottling lines allow bottlers to fill multiple products on the same line like water, CSD and hot filled juices enhancing the value of the investment.

Alle Artikel